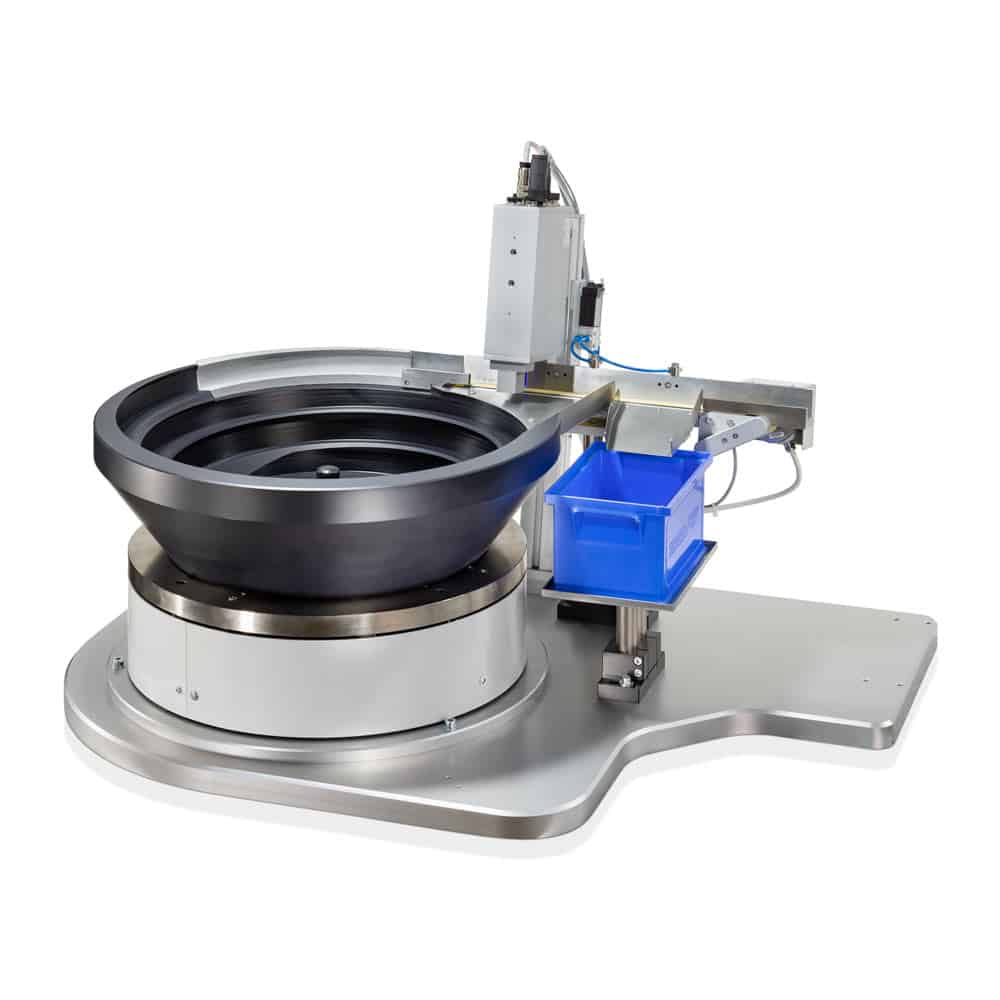

Feeding systems from nak

Reliable components in a feeding system in perfect interaction: For your very specific feeding requirements, nak combines proven drive components and conveyor units into a precisely matched overall system. nak conveyor systems are fast, robust and reliable. It is therefore no wonder that renowned automation providers trust in component feeders and systems from nak.

In the following we show some examples of feeding systems manufactured by us, which are already successfully in use with our customers.